When splicing fiber optic cables within a splice closure, there are several recommended methods and tools that can ensure successful and reliable splicing. Here are some commonly used methods and tools:

1. Fusion Splicing: Fusion splicing is the process of permanently joining two fiber optic cables by melting and fusing their ends together. It is considered the most reliable method for splicing fiber optic cables. The tools required for fusion splicing include:

a. Fusion splicer: This specialized device precisely aligns and fuses the fiber optic cables using an electric arc or laser.

b. Fiber cleaver: A fiber cleaver is used to cleanly and accurately cut the fiber optic cable ends before fusion splicing.

c. Fiber stripper: A fiber stripper removes the protective coating from the fiber optic cables to expose the bare fiber for fusion splicing.

2. Mechanical Splicing: Mechanical splicing is an alternative method for joining fiber optic cables by using mechanical connectors. Although not as robust as fusion splicing, mechanical splicing can be a quicker and more cost-effective solution. The tools required for mechanical splicing include:

a. Mechanical splice connectors: These connectors use precision alignment and mechanical fixtures to join the fiber optic cables.

b. Fiber cleaver: A fiber cleaver is still necessary for accurately cutting the fiber optic cable ends before mechanical splicing.

c. Fiber stripper: A fiber stripper is needed to remove the protective coating from the fiber optic cables for mechanical splicing.

3. Splice protection: Regardless of the splicing method, it is crucial to protect the splices within the splice closure to ensure their long-term reliability. Common tools for splice protection include heat shrink sleeves or splice trays that provide physical protection and maintain alignment.

4. Cleaning and inspection tools: Proper cleaning and inspection of the fiber optic cables before and after splicing are essential for optimal performance. Tools such as lint-free wipes, fiber optic cleaning solution, inspection microscopes, and fiber optic power meters may be required for cleaning and verifying the quality of the spliced fibers.

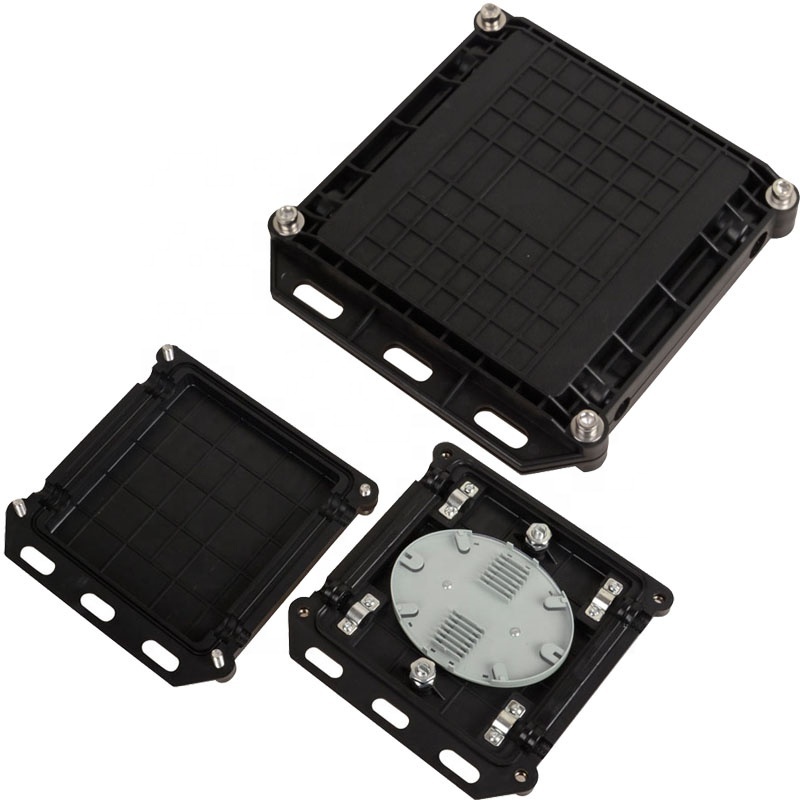

2 inlet 2 outlet joint closure fiber optic/splice closure 24 core IP68 optical fiber joint closure with PP+GF Material

English

English Español

Español